Aids for the energy saving and efficiency project

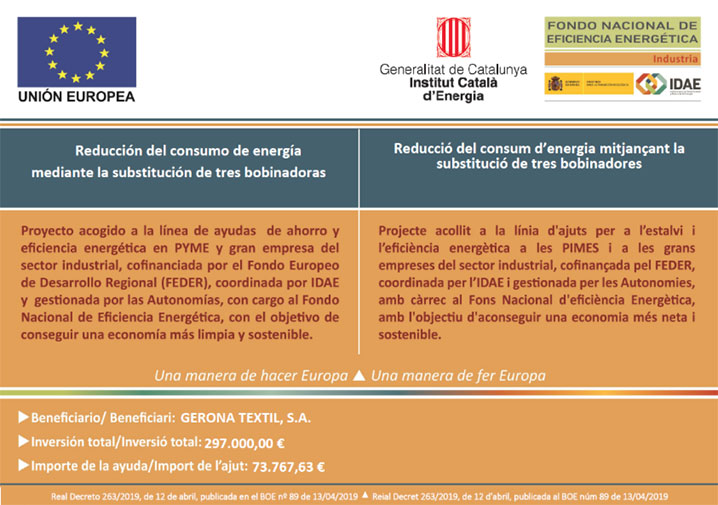

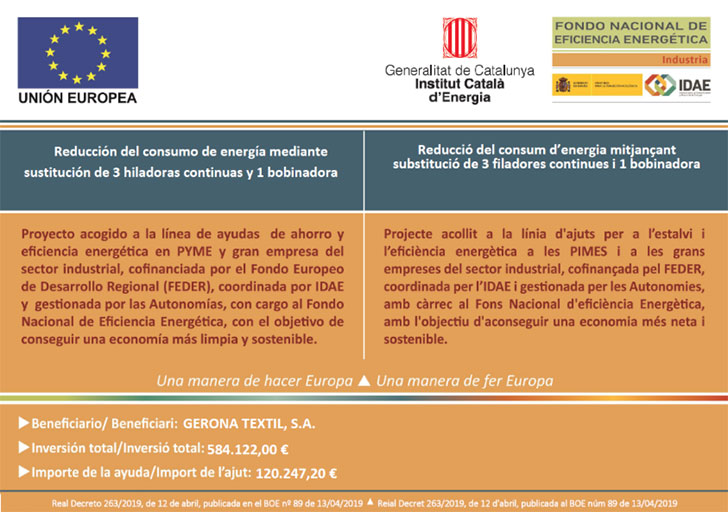

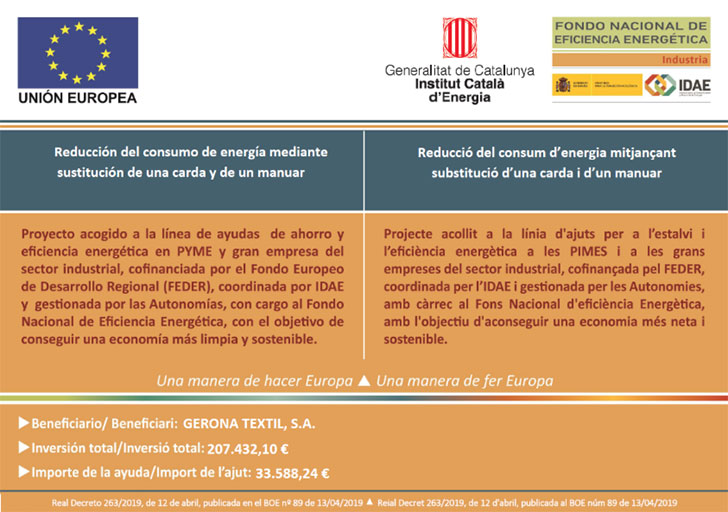

GERONA TEXTILE, S.A. has received aid for its energy saving and efficiency project “Reduction of energy consumption by replacing continuous spinning and winding machines”, co-financed by the European Regional Development Fund (ERDF), coordinated by IDAE and managed by the autonomies, with charge to the National Fund for Energy Efficiency, with the aim of achieving a cleaner and more sustainable economy. An energy saving and efficiency project has been developed consisting of the replacement of two machines in the production process, a continuous spinning machine and a winder, with new machines with high energy efficiency that allow the energy costs of the production process to be reduced. Thanks to the project, 26.45 teps are saved annually.

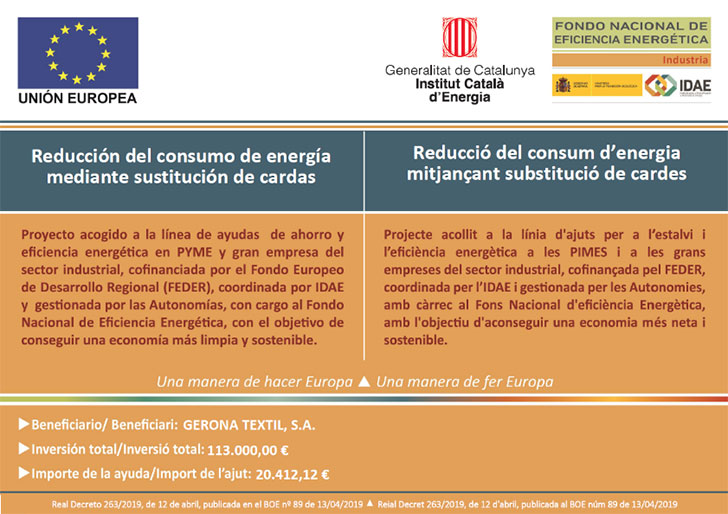

GERONA TEXTIL, S.A. has received aid for its energy saving and efficiency project “Reducing energy consumption by replacing cards”. The aid has been co-financed by Fondo Europeo de Desarrollo Regional (FEDER), coordinated by IDAE and managed by the autonomous regions, under the National Fund of Energy Efficiency, with the aim of achieving a cleaner and more sustainable economy. An energy saving and efficiency project has been carried out consisting of the replacement of two machines in the production process, two cards, with new ones with high energy efficiency that allow reducing the energy costs of the production process. Thanks to the project, 9.21 teps are saved per year.

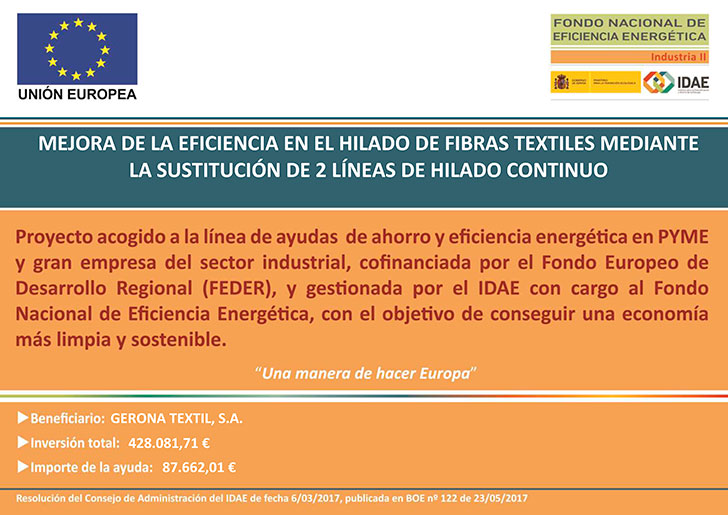

GERONA TEXTIL, S.A. has received an aid for its energy saving and efficiency project “Improvement of the efficiency in the spinning of textile fibers by the substitution of 2 lines of continuous spinning” through the INSTITUTE FOR THE DIVERSIFICATION AND SAVINGS OF ENERGY (IDAE), aid co-financed by the European Union through the 2014-2020 Smart Growth ERDF Operational Program. The result of the project has been the replacement of two lines of continuous spinning by two new lines of high energy efficiency: two continuous spinning machines and two wire winding machines have been replaced, resulting in an energy saving of 41.66 toe / year.